Is Raku Pottery Expensive to Make?

The mesmerizing crackle patterns and metallic sheens of Raku pottery might have you wondering: Will creating these stunning pieces break the bank? The truth is, Raku pottery sits at a fascinating crossroads between accessible craft and serious investment—and understanding the real costs can make the difference between diving in confidently and being caught off guard by unexpected expenses.

Whether you’re drawn to Raku’s dramatic firing process or its unpredictable artistic results, you’ll need to budget anywhere from a few hundred dollars for a basic setup to several thousand for a professional-grade studio. But here’s what many beginners don’t realize: your biggest expenses come upfront, while the ongoing costs can be surprisingly manageable once you’re established.

In this comprehensive guide, we’ll break down every expense you’ll encounter on your Raku journey. From essential equipment like kilns and safety gear to ongoing costs for clay, glazes, and propane. You’ll discover money-saving strategies, learn which tools are worth the investment, and understand exactly what it takes to transform raw clay into those coveted Raku masterpieces. By the end, you’ll have a clear roadmap for budgeting your own Raku pottery adventure, whether you’re planning a modest home setup or dreaming of a fully-equipped studio.

Affiliate Disclaimer: We are ambassadors or affiliates for many of the brands we reference on the website. As an Amazon Associate, I earn from qualifying purchases.

Understanding Raku Technique

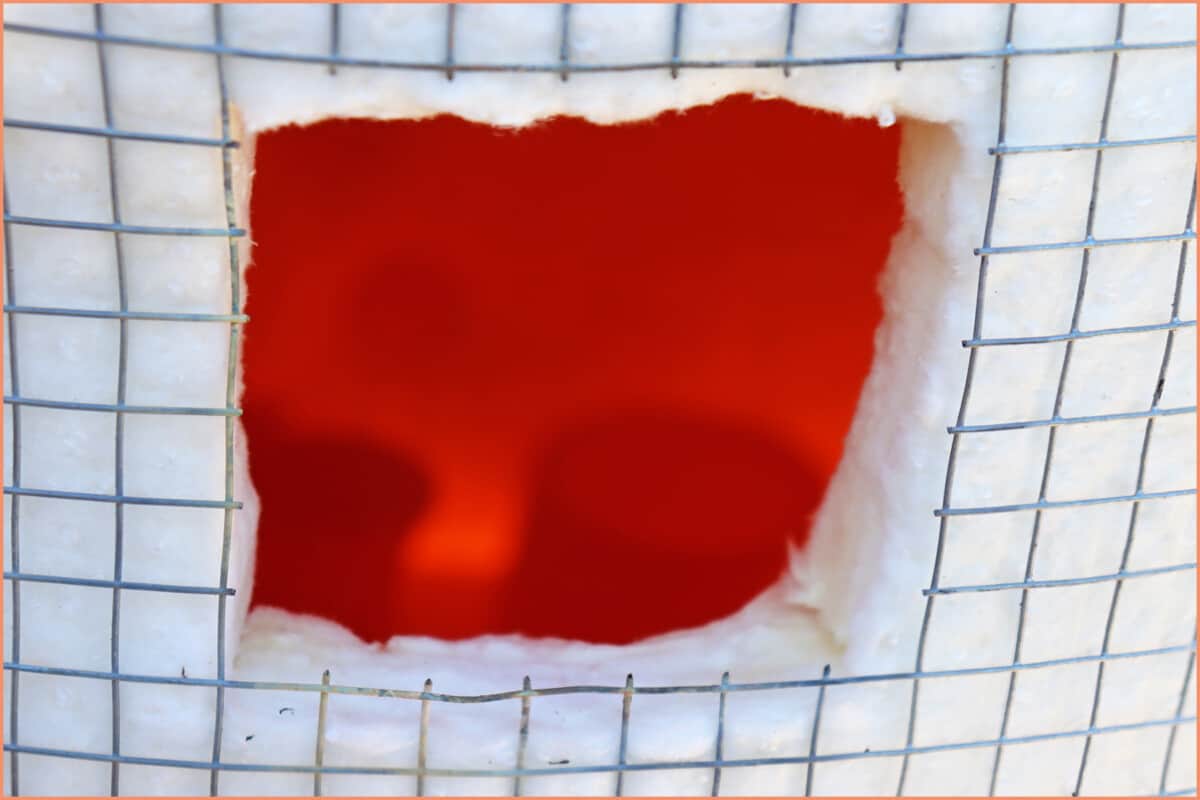

Raku is known for its distinctive approach, which involves low firing temperatures, rapid cooling, and a post-firing reduction process. The pottery is removed from the kiln while it is still red-hot and placed in a chamber with combustible material such as sawdust or paper. This causes the glaze to produce interesting colors and unpredictable patterns characteristic of raku pottery.

For more detailed information on Raku pottery, visit this link: “What is Raku Pottery.”

The Average Cost of Raku Clay and Glaze?

Raku pottery is renowned for its distinctive, unpredictable results, characterized by an unconventional firing process. To begin, I’ll first delve into the clays and glazes required for this art form and the average costs.

Clay Used to Make Raku Pottery

The price of raku clay can vary depending on the amount and quality. However, purchasing in bulk often results in a lower cost per pound. On average, you can expect to spend $15 to $30 for a 25-pound bag of clay.

Raku clay is specifically formulated to withstand the unique firing process used to create raku ceramics. When working with raku clay, you’ll notice it typically contains grog or sand, which enhances its ability to handle the thermal shock of extreme temperature changes during the firing process and reduces its shrinkage rate.

There are different clay bodies you can choose from. You can use the Standard Raku Clay, which is specifically designed for use in raku firing. It is an Earthenware clay that is porous and can withstand rapid temperature changes.

Although earthenware clays are popular for Raku, you can also use stoneware clay with sand or grog. Because the stoneware will only be fired to cone 06 or 04, the clay will remain porous. My Choice of clay for Raku is Laguna Soldate 60. It is a light-colored high-fire stoneware clay that works well for me. It takes thermal shock well, and I have had no cracks or breaks from this clay.

Glazes Used to Make Raku Pottery

Raku glazes vary in composition and price, and choosing a specific type can significantly affect the overall cost of making raku pottery. Glazes can range from $8 to $20 per pint, depending on the type and brand. You can also consider purchasing in larger quantities for better discounts.

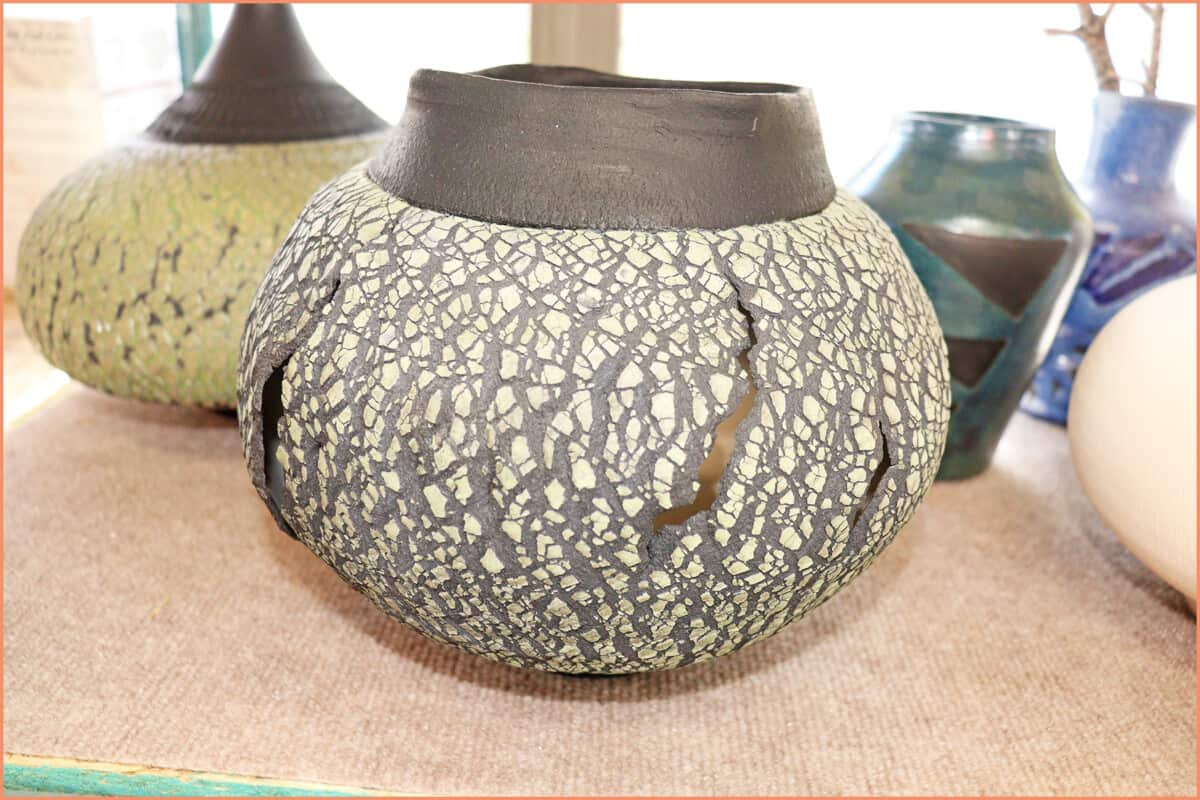

When selecting a glaze for your raku pottery, consider both the aesthetic and financial impacts. While it’s important to use high-quality glazes to achieve beautiful results, remaining mindful of your expenses can help maintain a more sustainable art practice. To help balance cost and quality, explore a Low-Temperature Glaze and various raku glaze options, like Mayco Peacock Matte 👇As shown in the picture below.👇

You can achieve a nice crackle effect by using a Low Fire Clear Glaze on a white clay body. You can also add stains to Low Fire Clear Glaze to create a unique look. That is the wonderful part of creating raku pottery.

The glazes used for the raku method must have a low-temperature melting point. Mid and High-fire glazes are not recommended for use with raku glaze because the temperature that raku is fired to is too low. However, this still leaves you with many other glazes to choose from.

It is important to note that raku glazes are not food-safe and should only be used for decorative purposes.

Kiln or Kilns Used for Raku Firing

Essential equipment for Raku pottery includes a Kiln or Kilns. In most raku processes, two kilns are used. If you don’t have access to a pottery kiln or raku kiln, they can be an investment.

The First Kiln

The first Kiln is used to bisque fire the clay, turning it into ceramic ware. Either Gas Kilns or Electric Kilns are used for the bisque firing.

For a new Electric Kiln, you can spend anywhere between $600 to $6500, depending on the size and quality of the kiln.

For a new Gas kiln, you can spend anywhere from $1,000 to $6,500, depending on the kiln’s size and quality.

The Second Kiln

The second is a raku kiln used to fire glazed bisque ware. Raku Kilns range from as low as $ 400 to $800 for a small portable model. You can also build your own raku kiln for around $200.

And $1,500 to $ 3,000 for a larger, more permanent setup.

Now, with pottery, there are exceptions to many rules. For example, gas kilns can work for both bisque and raku firing because the fuel source is the same.

The gas kiln can be used as a raku Kiln. It heats up more slowly and reaches higher temperatures for bisque firing, and heats up quickly for raku firing. There are still a few Differences Between a Gas and Raku Kiln.

Raku Firing Materials Needed

A Raku Firing needs a few more materials to complete the Raku process than a traditional kiln firing. This is achieved through specific materials and techniques that differ from those used in The Cost of Making Conventional Pottery in this Article.

Very Long Metal Tongs

The average cost for extra-long tongs is around $50. Long tongs are needed to remove the red-hot pottery from the kiln.

You need the Metal Tongs to be at least 36 inches long.

Safety Gear

To ensure your well-being while pursuing your passion, investing in the right safety gear is crucial. In this section, I’ll provide insights into their cost and functionality. Whether you’re a seasoned potter or just starting, understanding and using these safety tools can make your artistic journey both enjoyable and secure.

The average cost of safety gear ranges from $50 to $100, depending on the brand and quality.

A pair of Heat-Resistant Gloves is required for the firing process. These gloves play a critical role in protecting your hands and forearms from extreme temperatures during pottery firing. The high heat generated in kilns can cause severe burns, making heat-resistant gloves essential.

A pair of UV protection Safety glasses. UV-protected safety glasses shield your eyes when looking into the raku kiln to see the glowing pottery and witness the cones.

Heat Resistant Sleeves. While not as common as gloves, heat-resistant sleeves provide an extra layer of protection for your arms. Some potters choose to wear these sleeves in addition to gloves to safeguard their arms against accidental contact with hot surfaces.

With all of these materials in hand, you can start creating stunning works of art with unique designs that distinguish them from regular fired pottery ware.

Reduction Chamber

A reduction container and sand can be found for around $50 to $80, depending on the size and number of cans you need.

A trash can or another type of fireproof container is needed to place the red-hot pottery in. Small Trash Cans or metal containers are more popular for more control over the pots. Your container MUST have a fireproof cover. Sand is also needed at the bottom of your reduction chamber to protect it from overheating.

Combustible Materials Used in the Raku Process

The materials used to make raku pots can vary depending on the artist’s preference and the desired outcome. They are fairly inexpensive, and some are even free. Combustible materials are used to create the unique effects seen in raku pottery.

Common materials include sawdust and straw. Newspaper is a popular combustible material, especially for beginners, because it is easy to work with. If you choose to use newspaper, make sure it’s NOT shiny newspaper. You can also get creative and use organic combustibles such as dried leaves, thin branches, hay, wood chips, dried fruit, or vegetable peelings.

These materials are placed in a reduction chamber around the red-hot pottery, causing them to combust and create a reducing atmosphere. This reduction atmosphere is what produces the unique colors and patterns seen in raku pottery.

Education and Training

If you’re new to raku, taking a workshop or class can be beneficial. Learning the art of Raku pottery can be done through workshops, classes, or online tutorials. Workshops and classes can cost anywhere from $100 to $500, while an online How To Make Raku Tutorial with Video is free.

Time and Labor

While making Raku pottery can take many hours, the firing takes only 1 to 2 hours, a speedy process compared to a standard firing that can take over 24 hours. This can help save on energy costs.

To calculate the average cost of creating a single piece of Raku pottery, you’ll need to consider the utility cost and the time and labor invested.

Assuming you already have the equipment and training, creating a single piece can cost a potter anywhere from $20 to $50 in time and materials, depending on its size, intricacy, and how much your time is worth.

Details Created in Raku Pottery

The level of detail in raku pottery can also affect the cost of production. If you create intricate designs or add extra embellishments, the cost of materials may increase.

Additionally, the time it takes to create detailed pieces can also increase the overall cost of making raku pottery.

Methods Used to Make Raku

Some artists may use traditional methods that require more time and skill, while others may use modern techniques that are more efficient. Different methods will impact the overall cost of making raku pottery.

The cost of labor can vary depending on the methods used. You can choose to Burnish the Pot. Once burnished, you can use terra sigillata to further smooth the pot.

Terra Sigillata is a very refined clay slip. It is usually polished to a high sheen and low-fired. Apply 3-8 flowing coats to leather-hard or dry clay. Allow to dry and polish with a soft cloth or chamois.

Keep in mind that these figures are rough estimates, as costs can vary based on your location, the materials used, and the complexity of the piece. By understanding these components, you can create Raku pottery with a clear understanding of the expenses involved.

Raku Firing Process

The fuel cost for the kilns is typically $20-$40 per firing. This, again, depends on the size of the kiln or Kilns used.

After bisque firing your pottery, the raku firing process is a relatively quick and exciting way to create unique, one-of-a-kind pottery pieces. While it may not be the most cost-effective firing process, the results are often stunning and well worth the extra expense.

Sealing Raku Pottery

Raku pottery is not waterproof. Sealing raku pottery is another step in the production process. The Sealant Used to protect the pottery can vary in price, depending on the quality and quantity needed.

Using a high-quality sealant can help protect the pottery and extend its longevity, but it can also increase the overall cost of making raku pottery. This process can be time-consuming and require additional materials, which can increase the overall cost of making raku pottery from $5 to $30.

Production Quantity

The quantity of raku pottery produced can also affect the cost of production. If an artist produces a large quantity of raku pottery, they may be able to purchase materials in bulk, which can help reduce costs. Additionally, if an artist produces a small quantity of raku pottery, material costs may be higher due to the smaller scale of production.

Origin of Raku Pottery That Contributes to the Cost

Raku pottery originated in Japan in the late 16th century. Raku’s principles highlight simplicity, natural beauty, and humility, rooted in Buddhist teachings and Sen no Rikyu’s ideals. The Raku family in Kyoto has preserved this art for many generations. Raku pottery is an unparalleled example of wabi-sabi, the Japanese aesthetic of finding beauty in imperfection and transience.

Its unique process and philosophy have also attracted attention and appreciation from Western ceramic artists, who have adapted and expanded upon the traditional Japanese raku technique. With its continued evolution and growing global interest, raku pottery remains an important and vibrant aspect of the ceramic art world.

Conclusion

Remember, these are rough estimates, and actual costs can vary widely based on location, preferences, and specific choices. It’s always a good idea to shop around and do some research specific to your local area and needs.

It is important to note that the cost of Raku pottery can vary greatly depending on the artist, the quality of the materials used, and the complexity of the design. Some Raku pottery pieces may be relatively affordable, while others may be quite expensive.

Overall, if you are interested in making Raku pottery, it is important to be prepared for the associated costs. However, the unique beauty and value of the finished product can make the investment worthwhile for those passionate about the art form.